Shopping cart

Your cart empty!

Terms of use dolor sit amet consectetur, adipisicing elit. Recusandae provident ullam aperiam quo ad non corrupti sit vel quam repellat ipsa quod sed, repellendus adipisci, ducimus ea modi odio assumenda.

Lorem ipsum dolor sit amet consectetur adipisicing elit. Sequi, cum esse possimus officiis amet ea voluptatibus libero! Dolorum assumenda esse, deserunt ipsum ad iusto! Praesentium error nobis tenetur at, quis nostrum facere excepturi architecto totam.

Lorem ipsum dolor sit amet consectetur adipisicing elit. Inventore, soluta alias eaque modi ipsum sint iusto fugiat vero velit rerum.

Sequi, cum esse possimus officiis amet ea voluptatibus libero! Dolorum assumenda esse, deserunt ipsum ad iusto! Praesentium error nobis tenetur at, quis nostrum facere excepturi architecto totam.

Lorem ipsum dolor sit amet consectetur adipisicing elit. Inventore, soluta alias eaque modi ipsum sint iusto fugiat vero velit rerum.

Dolor sit amet consectetur adipisicing elit. Sequi, cum esse possimus officiis amet ea voluptatibus libero! Dolorum assumenda esse, deserunt ipsum ad iusto! Praesentium error nobis tenetur at, quis nostrum facere excepturi architecto totam.

Lorem ipsum dolor sit amet consectetur adipisicing elit. Inventore, soluta alias eaque modi ipsum sint iusto fugiat vero velit rerum.

Sit amet consectetur adipisicing elit. Sequi, cum esse possimus officiis amet ea voluptatibus libero! Dolorum assumenda esse, deserunt ipsum ad iusto! Praesentium error nobis tenetur at, quis nostrum facere excepturi architecto totam.

Lorem ipsum dolor sit amet consectetur adipisicing elit. Inventore, soluta alias eaque modi ipsum sint iusto fugiat vero velit rerum.

Do you agree to our terms? Sign up

Table of Contents

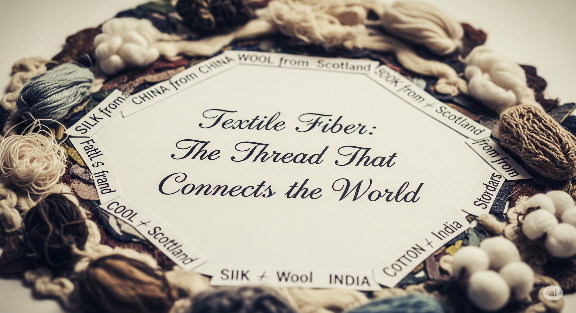

What is a Textile Fiber?

Classification of Textile Fibers

Natural Fibers – Types, Sources & Uses

Man-Made Fibers – Regenerated & Synthetic

From Fiber to Fabric – The Lifecycle

Properties of Fibers

Industrial & Fashion Applications

Sustainable Fibers & Eco Impact

Future Innovations in Fibers

Summary & Final Thoughts

A textile fiber is the fundamental unit used to manufacture yarns, fabrics, and ultimately, all kinds of textile products . Think of fibers as the DNA of textiles — they determine everything from softness to stretchability.

To be classified as a textile fiber, a material must meet the following:

Length: Must be longer than its width (high aspect ratio).

Flexibility: Must be bendable and elastic.

Strength: Must withstand tension during weaving.

Spinnability: Should be able to form yarn.

Comfort: Should not irritate human skin.

Textile fibers are primarily classified into two categories:

Derived from plants, animals, or minerals.

Biodegradable

Renewable

Chemically processed in labs or factories.

Includes regenerated and synthetic fibers.

Often petroleum-based

From the seed hairs of the cotton plant.

Breathable, soft, hypoallergenic.

Widely used in t-shirts, jeans, and bedding.

Extracted from the stalk of flax plants.

Stiffer and cooler than cotton.

Wrinkles easily, used in summer clothing.

Coarse, golden fiber from the jute plant.

Used in gunny bags, sacks, mats.

One of the most eco-friendly fibers.

Very strong, mildew-resistant.

Used in denim, canvas, eco-fashion.

Chinese plant fiber, similar to linen.

Silky, lustrous appearance.

Sourced from sheep .

Naturally insulating, retains warmth even when wet.

Types include: Merino, Shetland, Mohair, etc.

Harvested from silkworm cocoons .

Luxurious, shiny, and soft.

Costly due to labor-intensive process.

From undercoat of Cashmere goats.

Extremely soft and warm.

From the Alpaca of South America.

Silky and hypoallergenic.

Resistant to fire and chemicals.

No longer used due to health hazards (causes cancer).

These are made by chemically treating natural polymers, typically cellulose.

Soft, breathable, similar to silk.

Common in linings, dresses, and curtains.

A form of rayon with high absorbency.

Derived from beech trees. Strong, resistant to shrinking.

Eco-friendly, fully biodegradable.

Used in sustainable fashion lines.

Derived from petrochemicals and created by polymerization.

Durable, wrinkle-resistant, quick-drying.

Found in activewear, jackets, and home textiles.

Elastic, strong, water-resistant.

Used in stockings, ropes, sportswear.

Soft like wool, lightweight, resists moths.

Used in sweaters, blankets.

High elasticity, used in sportswear, leggings, swimwear.

Source – Collect from plants, animals, or create synthetically.

Preparation – Clean, card, and align fibers.

Spinning – Twist fibers into yarn.

Weaving/Knitting – Create fabrics from yarn.

Finishing – Dyeing, printing, treating (e.g. wrinkle resistance).

Fabrication – Tailoring into garments and goods.

| Property | Natural Fibers | Synthetic Fibers |

|---|---|---|

| Eco-friendliness | High | Low |

| Moisture Absorption | Good | Poor |

| Durability | Moderate | High |

| Comfort | Excellent | Moderate |

| Cost | Often higher | Often lower |

| Dyeability | Easy | Depends |

Cotton for casualwear

Silk for luxury garments

Polyester for activewear

Curtains, carpets, pillow covers, upholstery

Filters, geotextiles, conveyor belts, tents

Surgical gowns, bandages, implants (biotextiles)

Bulletproof vests (Kevlar)

Fire-resistant suits

Smart fabrics for health monitoring

The fashion industry is the second-largest polluter

10,000+ liters of water are needed to produce 1 kg of cotton!

Plastic microfibers from synthetic clothes pollute oceans

Organic cotton

Recycled polyester

Hemp, bamboo

Biodegradable rayon (Lyocell)

Mycelium leather – made from fungi

Pinatex – from pineapple leaves

Clothing from recycled ocean plastic

Smart Textiles: Embedded sensors for health data.

Self-cleaning Fabrics: Nano-coated textiles repel dirt.

Bioengineered Silk: Lab-grown spider silk is stronger than steel!

Bacterial Fibers: Created by microbes in fermentation tanks.

Space-Ready Fabrics: Thermally insulated fibers for astronauts.

Textile fibers are not just materials, they are a living history of culture, science, industry, and sustainability. From humble natural beginnings to cutting-edge biosynthetic innovations, the journey of a fiber tells the story of civilization itself.

As consumers and creators, our awareness and choices can shape the next generation of textiles — one that’s ethical, sustainable, and innovative .